The German Maritime Centre issued an invitation to tender in 2019 to conduct a study entitled The Current International State of Technology with Respect to the Development and Application of Adhesive Bonding in Shipbuilding. The Center of Maritime Technologies was contacted and commissioned to conduct the study.

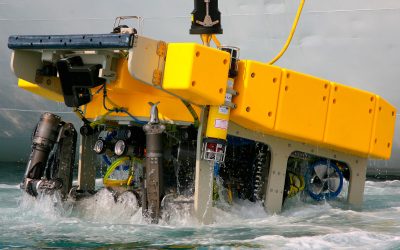

The study examined the application of adhesive bonding in shipbuilding, boatbuilding, inland shipbuilding, and in the offshore industry; its main focus being on shipbuilding. Increasing the use of adhesive bonding in shipbuilding offers great potential for shipyards to boost their competitive position and consolidate their lead in technology.

Summary

The German Maritime Centre issued an invitation to tender in 2019 to conduct a study entitled Research into the Current International State of Technology with Respect to the Development and Application of Adhesive Bonding in Shipbuilding. The Center of Maritime Technologies was awarded the contract and commissioned to carry out the study.

Background

The German shipbuilding industry is under intense pressure from international competition. Maritime sector products are complex and highly sophisticated structures which are exposed to the strain of harsh environmental conditions and are expected to meet constantly growing demand for environmental and resource efficiency standards.

New materials and production methods play an important role alongside research on propulsion technologies and alternative fuels. Maritime products made in Germany are becoming increasingly sophisticated, creating growing demand for new bonding methods which enable a high degree of flexibility in production. These are needed, for example, for modifications or reworking at later stages of construction, and for retrofitting and repair work once the product is in operation.

The use of lightweight construction materials can make the implementation of technical innovations possible and subsequent weight reductions help decrease resource consumption and lower emissions. Adhesive bonding will inevitably play an important role as it is a joining technology particularly suitable for lightweight construction.

Objectives

The study focuses on the increased application of adhesive bonding in practice. It should:

- depict the current state of technology and research, and the spreading adoption of adhesive bonding;

- analyse the current situation in regard to regulations and standards for the application of adhesive bonding in shipbuilding, inland shipbuilding and boatbuilding;

- identify potential applications and cost savings;

- recommend a structure for the requisite development of standardised regulation and for subsequent research activities.

The anticipated findings are meant to benefit the entire German shipbuilding industry, including boat building companies and inland shipyards. A more widespread and expedient application of adhesive bonding, as recommended by the study’s findings, could consolidate the lead in technology of German shipyards.

Findings

An advisory group of experts was involved in the study in order to ensure a high level of practical relevance and thus enable the German shipbuilding industry to derive the greatest possible benefit from the study’s findings. As these findings were intended to reflect as many segments of the maritime sector as possible, representatives from shipbuilding, inland shipbuilding, boatbuilding, classification societies and research institutes were included in the advisory group.

1. State of research and technology

The analysis of the current state of technology and research shows that adhesive bonding—due to its widespread use within the automotive and aerospace industries—is essentially well researched. Compared to other joining methods, adhesive bonding offers the special advantage of being able to bond different materials and can therefore serve as an enabling technology for lightweight construction. Lightweight construction is, alongside the continuing development of propulsion technologies, an important lever for shipbuilding to mitigate its climate footprint.

Adhesive bonding is already widely used in boatbuilding. According to the current state of technology, adhesive bonding is the most suitable joining technique when using fiber-composite materials. It is used for a wide range of joining tasks, including as a structural adhesive for hull-to-deck joints and for smaller assembly bonding applications.

In shipbuilding, where steel continues to play the predominant role, bonding is currently used mainly for the assembly of technical equipment. Welding in particular, and joining techniques such as bolting are established standards. Of great importance for shipbuilding is that adhesive bonding can be used as a “cold” joining process in the production stage after completion of hot work processes, making a flexible response to changes possible.

Overall, there is potential for expansion for adhesive bonding applications in the shipbuilding industry. The shipyards have understood the advantages of adhesive bonding as a joining technology and are seeking to increase its applications.

2. Regulations and standards

The experts consulted for the study consider the current regulatory environment as the greatest obstacle to the more widespread use of adhesive bonding in shipbuilding. The survey shows that shipyards have a strong interest in standardised and practical set of rules and guidelines.

Currently, the various classification societies have different sets of rules and guidelines for individual areas of application (e.g. a set of rules for repairs, a set of rules for non-structural adhesive bonds, etc.). There is no uniform industry standard. Cross-sectoral standards provide good general orientation with regard to process requirements and quality control, but do not take into consideration aspects specific to shipbuilding.

At the present time, case-by-case approval of adhesive joints is the rule. This approach is time consuming and the outcome is difficult to foresee. Clearly defined requirements, which would make approval more predictable, do not exist for many areas, such as design and testing.

3. Practical application

Even if the decision to use adhesive bonding in shipbuilding is usually taken for technical reasons, its application has to be cost efficient. A study of the steps involved in the process has shown that compared to welding, adhesive bonding offers more potential for cost savings, in particular due to the reduced need for reworking. The costs of overall construction can be also reduced, for example, thanks to lower material costs. Furthermore, the application of adhesives can dampen sound and vibration throughout the entire structure.

4. Recommendations

The study proposes a structure and content for the requisite development of standardised regulation. This recommendation is based on an analysis of existing regulations, such as Welding in Shipbuilding or Production Standard of the German Shipbuilding Industry, both compiled by the VSM (Verband für Schiffbau und Meerestechnik – Association for shipbuilding and marine technology). Requirements for operating licenses and general quality practices—already defined in detail in other sets of regulations and standards—can be used as points of reference in the development of regulations; however, they have to be more precisely elaborated and formulated, for example, with respect to the drafting of content specific to shipbuilding.

In addition to determining and defining content, the procedures used to draft these guidelines are essential in developing a set of regulations destined to serve as a uniform binding industry standard. As a first step, the study recommends setting up a (moderated) regulation committee. The shipyards should be the central players in this committee, supported by research institutes, manufacturers of adhesives and other upstream suppliers, as well as classification societies. The medium- to long-term goal should be international standardisation for which the national industry standard can serve as a basis.

The study (only in German) is available here.